Conception

Lohr develops human and technical expertise which is constantly adapting to the latest technologies.

Designing solutions involves a harmonised sharing of resources and skills for the implementation of systems engineering. Our tactical and logistics vehicle solutions are considered as systems in their own right, acting with a “system of systems” environment.

The project platform enables our experts to agree on the needs expressed, the development of the product, production capacity, in service support and end-of-life recycling.

Whether in terms of innovation, development or adaptation, design is based mainly on:

The technical hub :

- It designs and develops each product, ensures its maintainability and drafts the related documentation.

- It takes into account the production capacities right from the development phase.

- It conducts industrial validation and technical qualification via the development, monitoring and implementation of prototypes and first of series.

- It correlates the results of the calculation department with the measurements made during the dynamic tests.

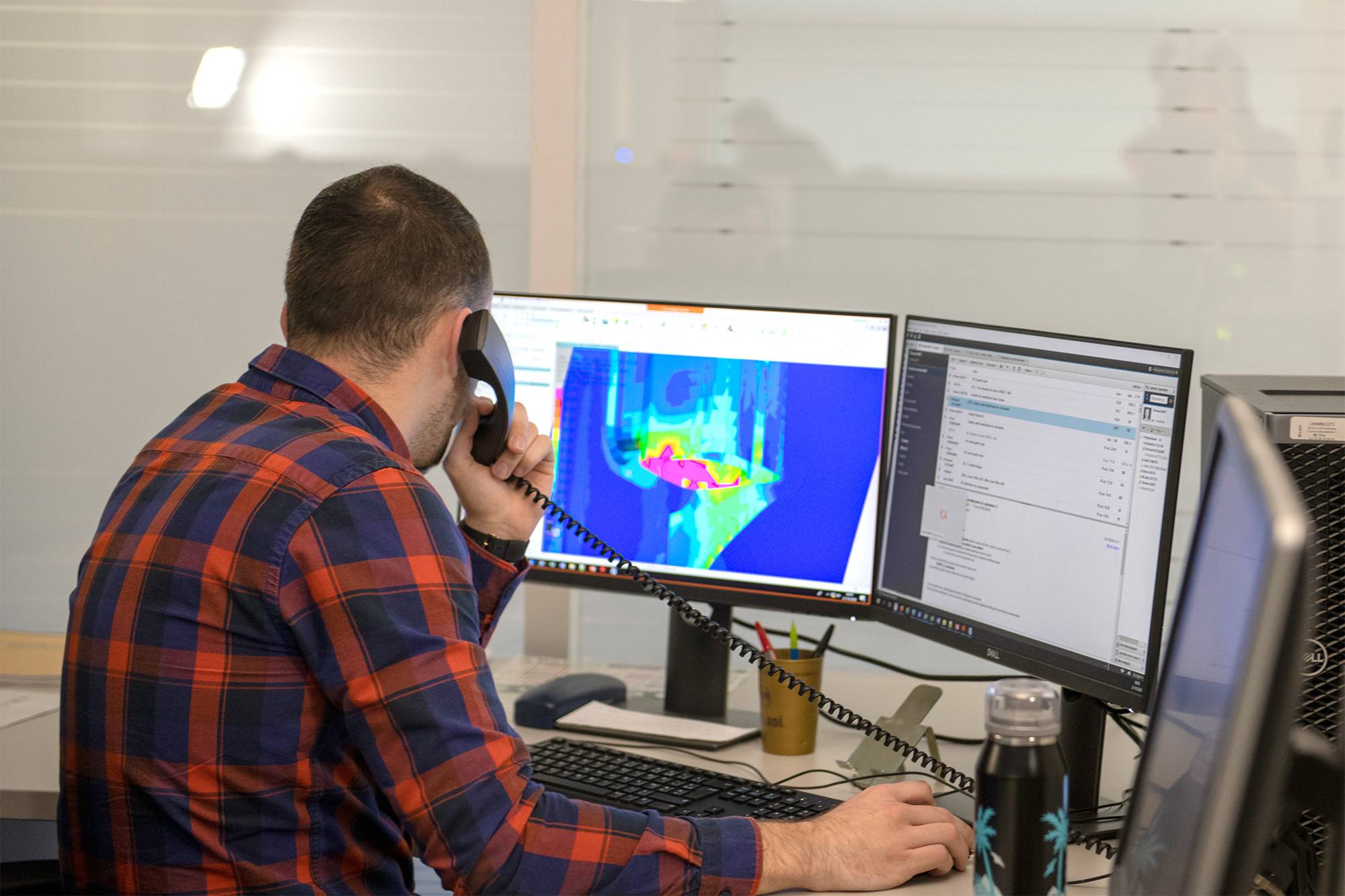

The calculation and simulation department :

- It models the structures in finite elements.

- It anticipates the behaviours of the structures by simulation, particularly the fatigue and the ballistic, anti-blast and anti-mine resistance of the vehicles, bodies and cabs developed.

- It analyses the consequences of product definition developments after their industrialisation.

- It calculates the resistance of the structures according to the life profiles of the equipment.

Tests

Testing is essential at the design and production stages of our equipment. They allow us to guarantee their longevity and safe use. Since the beginning of the company, we have always been demanding to test rolling stock as well as more or less critical sub-assemblies.

Lohr Industrie has an internal department dedicated to the testing of the Carrier, Cristal and Modalohr products. This autonomy in terms of testing guarantees reactivity and adaptation during the different phases of product development:

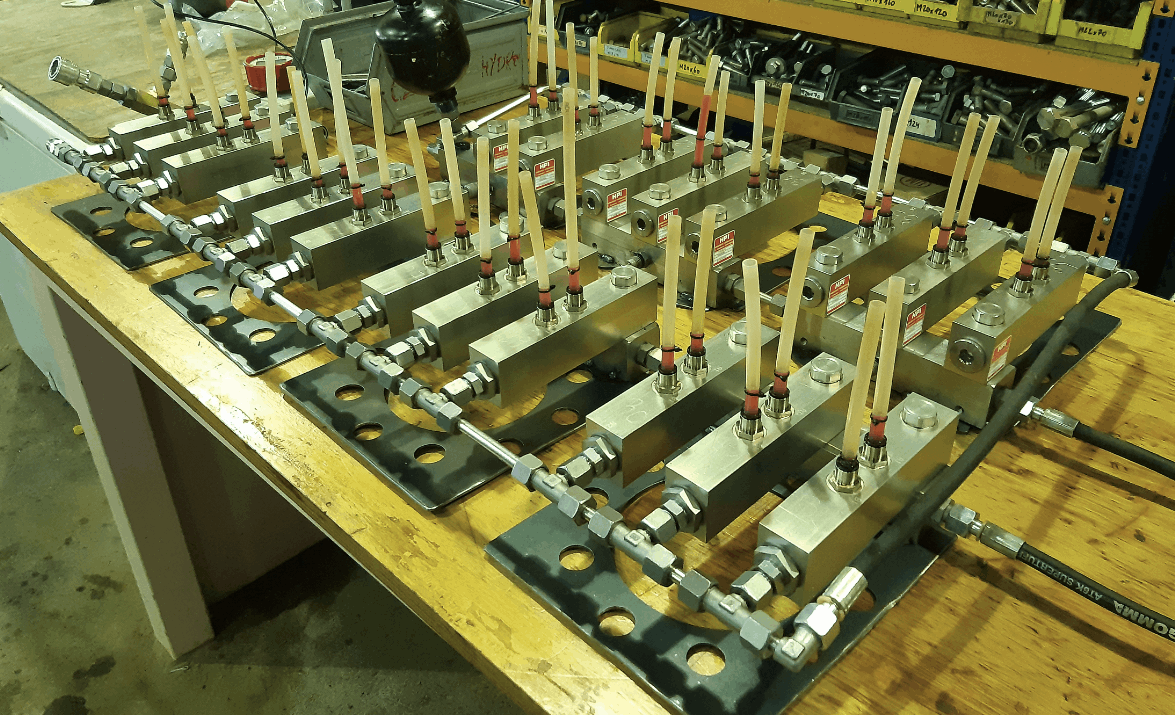

- Approval of materials and sub-assemblies in accordance with the standards and directives in force

- Qualification of complete vehicles or supplier components under severe conditions of use

- Design assistance for engineering offices

- Consolidation of numerical models for structural calculations (recalibration between stress values calculated on numerical models and reality)

- Expertise and determination of the origin of a defect reported by the after-sales service in order to improve the design.

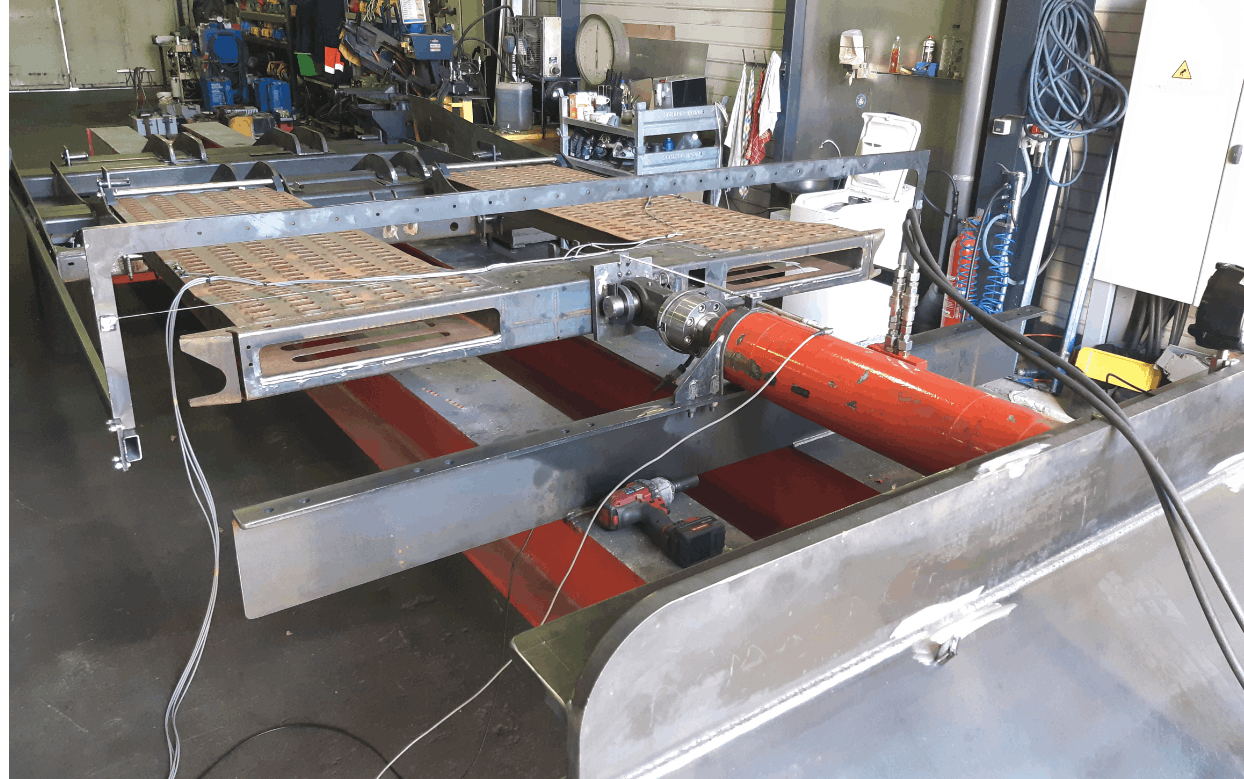

We can carry out on-board tests on rolling stock in its context of use or on sub-assemblies in the workshop, on a bench:

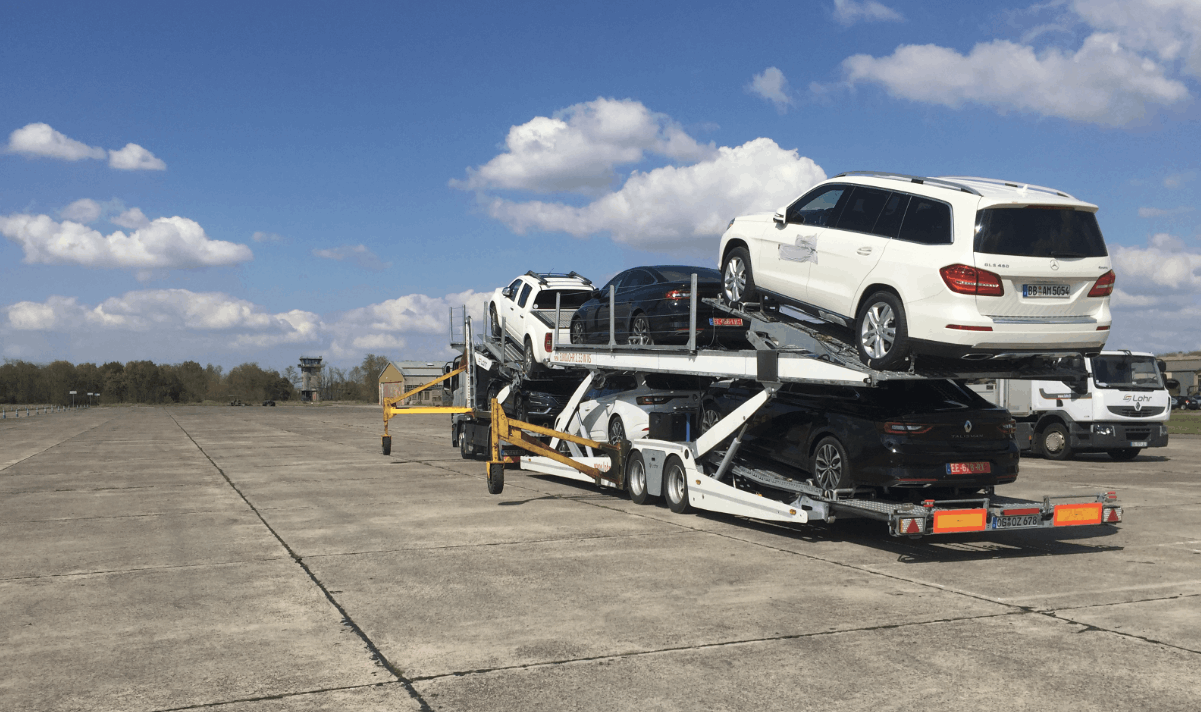

- Dynamic rolling of complete rolling stock with instrumentation (e.g.: rolling of a car carrier on an old landing strip)

- Application of extreme loads on complete equipment or sub-assemblies (e.g.: verification of the resistance of an underride bar at the rear of car carriers)

- Mechanical fatigue loading (several million cycles) of sub-assemblies on a test bench (e.g.: Cristal rolling stock)

We benefit from all the manufacturing means of the factory for the realization of test assemblies and specific benches:

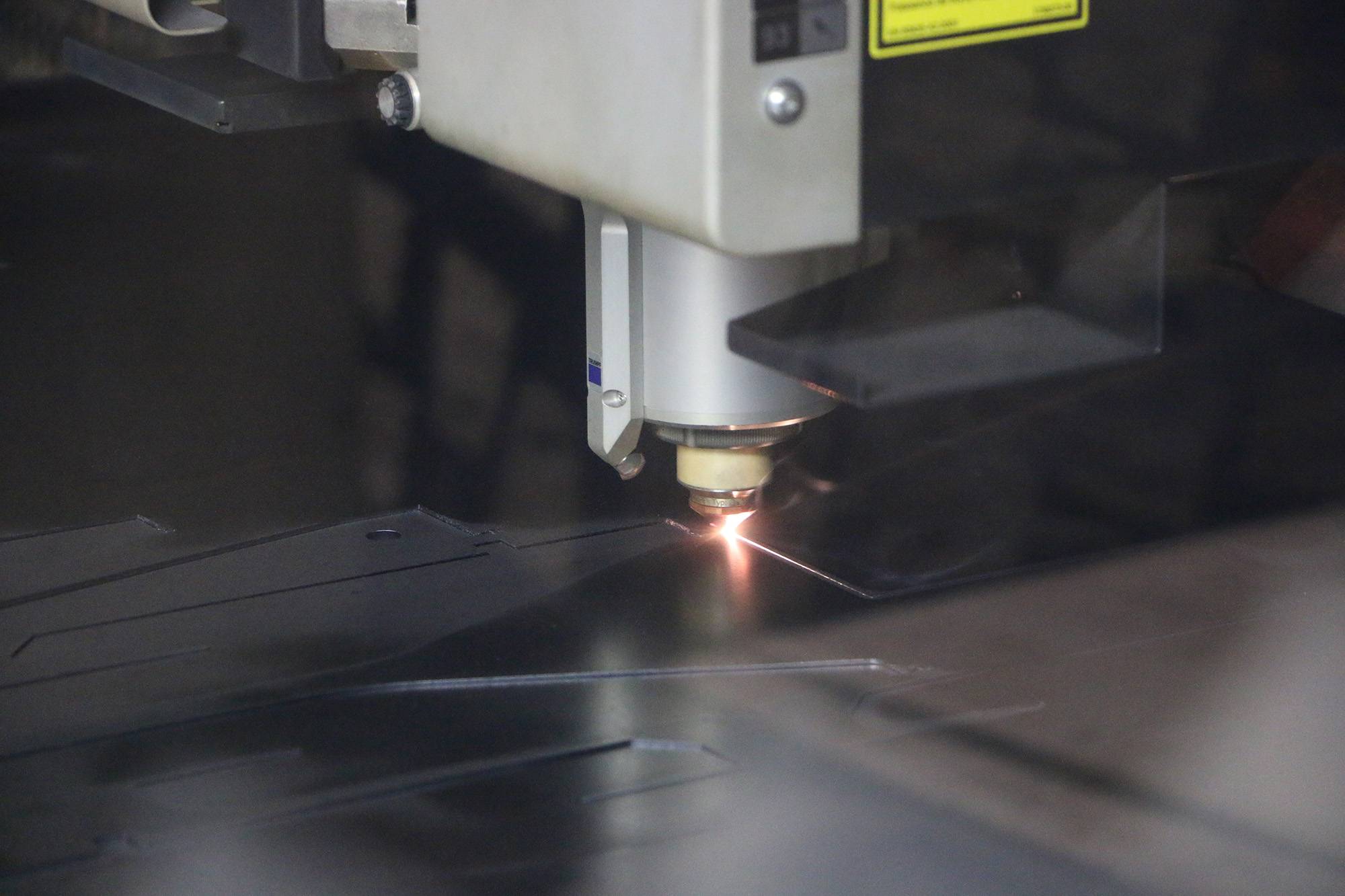

- 3D design and modeling

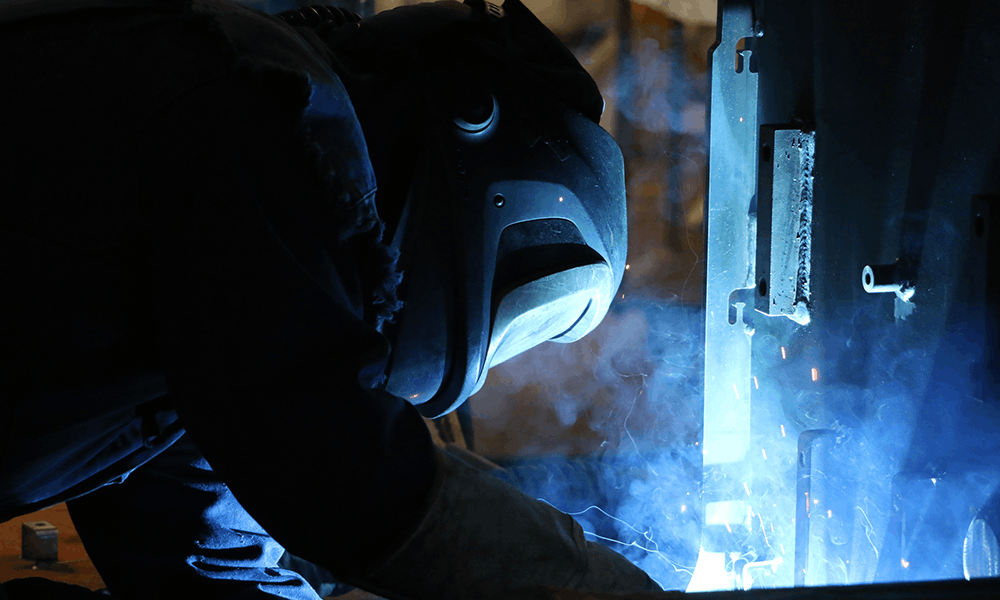

- Manufacturing of welded structures (cutting, bending, welding, machining).

We are equipped with a wide range of instruments allowing the measurement and recording of many physical quantities:

- Hydraulic and pneumatic pressure

- Efforts

- Surface stresses

- Displacement, speed, angle

- Acceleration

- Temperature

- Voltage, current

- Sound

English

English

Français

Français

Deutsch

Deutsch

Español

Español

Русский

Русский